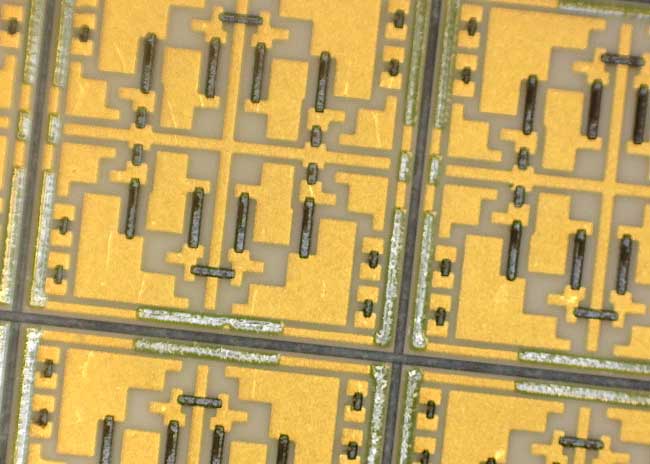

Metallization is the application of metal to the surface of the ceramic. This process involves screening, drying, and firing the metal paste onto the ceramic. Metallization screening applies conductor traces and pads to the surface of the substrate.

In addition to screening, metallization can also be applied to vias, or holes through substrate materials. These vias can be either filled or plated. Vias can also be filled through a dielectric, which connects layers in a multi-layered substrate.

Available Metals

Gold (Au)

Virtually impervious to anything in the atmosphere—no rust, no oxidation. Easy to bond fine gold wire to serve as connectors to other components or conductor traces.

Silver (Ag)

Silver has lower resistivity/higher conductivity than gold. More economical than gold.

Platinum Silver (PtAg), Palladium Silver (PdAg), Platinum Palladium Silver (PtPdAg)

Good for soldering. More economical than gold. Most substrates use one of these alloys rather than pure silver for better resistance to oxidation.

Why Micro-Precision Technologies

- Small Lot Friendly

- New Product Introduction (NPI)

- Consigned or Full Turnkey Assemblies

- Class 10,000 Cleanroom for Assembly (0.5 micron per cubic foot)

- Class 100 Cleanroom for Pre-Cap Inspection (0.5 micron per cubic foot)

- AS9100D ISO-9001:2015 Certified

- MIL-PRF-38534 Class H Qualified

- QML-38534 Listed

Download Documents (PDFs)

Capabilities Brochure | Thick Film Processing Notes

Talk To Our Engineers

- P: 603-893-7600

- Below is our Quick Contact form. To send us a file, use our Quote form instead.

Certifications

MPT is MIL-PRF-38534 Class H qualified since 1998, QML-38534 listed, certified by DSCC (Defense Supply Center, Columbus, OH). MPT is AS9100D ISO 9001:2015, and ITAR registered.