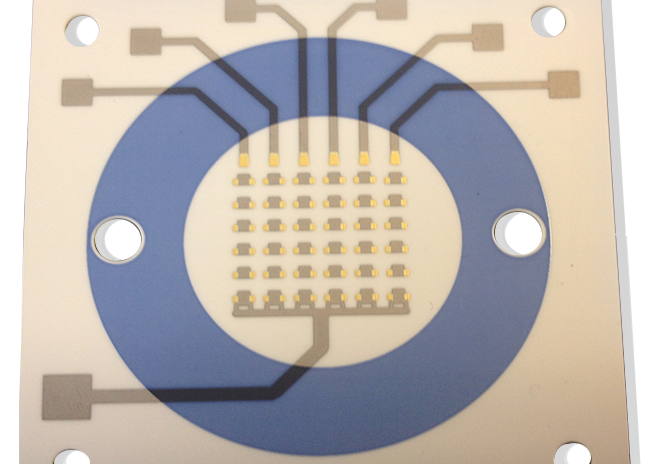

High power light-emitting diodes (LEDs) can use 350 milliwatts or more in a single LED. Most of the electricity in an LED becomes heat rather than light (about 70% heat and 30% light). If this heat is not removed, the LEDs run at high temperatures, which not only lowers their efficiency, but also makes the LED less reliable. Thus, thermal management of high power LEDs is crucial. Below is a table that details thermal management of FR4 material vs Alumina based materials:

| Material | (W/m-K) |

|---|---|

| Alumina | 28–35 |

| Aluminum Nitride | 140–180 |

| Beryllium Oxide | 170–280 |

| FR-4 | 0.8–1.1 |

Thick film processing of alumina based materials is a selective additive deposition process which uses material only where it is needed. Therefore thermal interface materials (heat sinks) are not needed for circuit building. Processing steps are reduced, along with the number of materials and amount of materials consumed.

Why Micro-Precision Technologies

- Small Lot Friendly

- New Product Introduction (NPI)

- Consigned or Full Turnkey Assemblies

- Class 10,000 Cleanroom for Assembly (0.5 micron per cubic foot)

- Class 100 Cleanroom for Pre-Cap Inspection (0.5 micron per cubic foot)

- AS9100D ISO-9001:2015 Certified

- MIL-PRF-38534 Class H Qualified

- QML-38534 Listed

Download Documents (PDFs)

Capabilities Brochure | Thick Film Processing Notes

Talk To Our Engineers

- P: 603-893-7600

- Below is our Quick Contact form. To send us a file, use our Quote form instead.

Certifications

MPT is MIL-PRF-38534 Class H qualified since 1998, QML-38534 listed, certified by DSCC (Defense Supply Center, Columbus, OH). MPT is AS9100D ISO 9001:2015, and ITAR registered.